Hi Everyone, here are the first two lots of pictures I received from our members for publication on our web site. The first pictures came from Dave Line, and the next lot of pictures came from Geoff Potter.

Now that I am the proud owner of a long hole borer, here are a couple of lamps I made last week.

The 1st (on the left) is 380 mm tall with a base of 175 mm in diameter. It is made out of an old table leg I found at the tip, I think it is laminated Pine.

The 2nd (on the right) is 250 mm tall with a base of 130 mm in diameter.

The main body and base are Ash with sycamore inlay, I burnt a couple of rings just to finish it off.

Photo 1 Showing a similar log ( both from the firewood pile ). I think it is Scots Pine. Maybe I’m wrong?

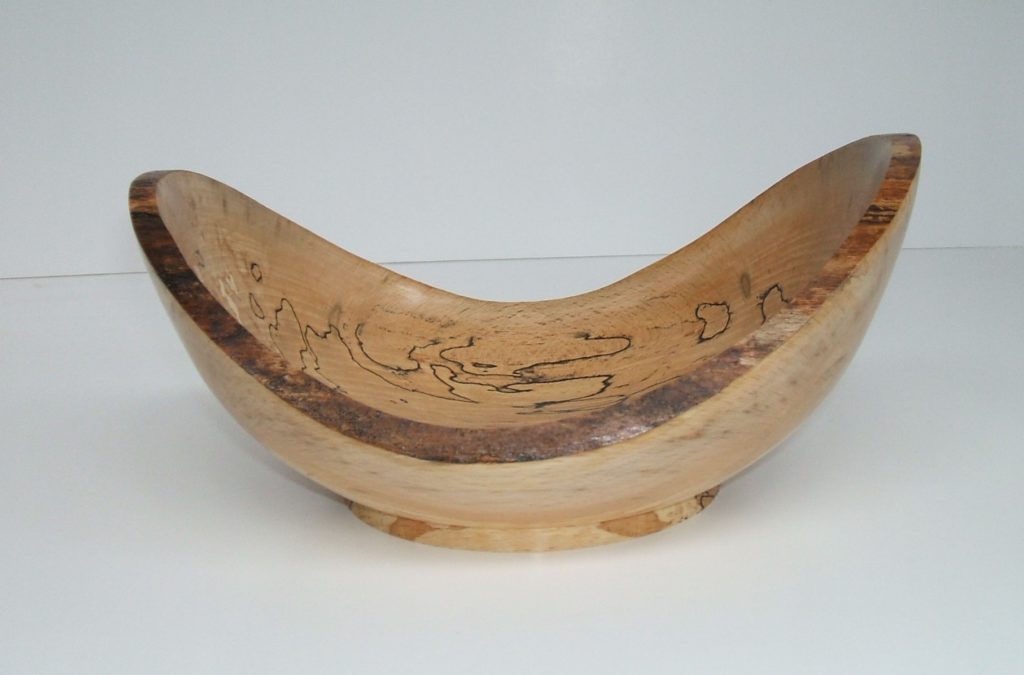

Photo 2 The finished bowl 15cm by 7cm high. I like my bark edge to be wide – so that it shows off the bark. I had to use some superglue to stabilise some of the bark but not much. The outside of the bowl and the bark edge is finished in Melomine, the inside is finished with ‘food safe oil’ so that it is just ready for the salted peanuts to be delivered by Tesco’s next week. The Melomine was put onto the bowl with a cloth and buffed to a shine following the scraper, sanding sealer and 80 (tut tut …some small amount ) then 180/240/400 grit power drill abrasive disks. The bark was painted with Melomine with a brush.

Photo 3 The base. Reversed on to a jam chuck so that I could remove the spigot and apply a little decoration.

Photo 4 Problem 1. The highest side on the inside of the bowl is hard to finish. The bowl gouge is supported then unsupported as the bowl revolves so you get a vibration. At the same time the gouge is traversing the end grain. This leads to tear out and a darker patch even after a lot of sanding.

Photo 5 Problem 2. The knots in the bowl were loose and these needed to be left overnight with my cheap Pound Store superglue and pressed in fine wood shavings. I think this was reasonably successful. The reason it was left overnight is that previous superglue application looked to have set – but sprayed out when I switched the lathe on and put some spots on my glasses which will not come off. Thankfully not my eyes!

Approximately 3 hours work ie an hourly rate of £7 ?, unless I give it away! Any criticisms, hints or tips gratefully received from anyone.

Geoff Potter

Our thanks go out to both Dave and Geoff for sharing their work with us, please keep the pictures and their story coming.