Our meeting on Thursday 7th December 2023 was organized by Alan Smith, Alan’s theme for the meeting was using green wood (I.E. un-seasoned wood ). He had arranged for all 5 of the club lathes to be in use, with 4 club members plus himself doing the demonstrating.

Green wood or un-seasoned wood can be worked in several different ways, the most common way to use green wood is to part turn it then to allow it to dry further in a dry but cool atmosphere, it can then be returned to the lathe and finished off. The initial turning would be taken down to about 80% leaving the remainder to be worked after the wood had dried to a workable level of moisture content. The other common way to use green wood is to cut it very thin, down to about 2mm in wall thickness, this system is best used in Natural Edged items where the top is left natural, there may be some movement with this type of turning so it needs to be carried out all at the same time, don’t leave it for any length of time before doing your final cut, if you do you may find the item is no longer round and your cuts will be uneven.

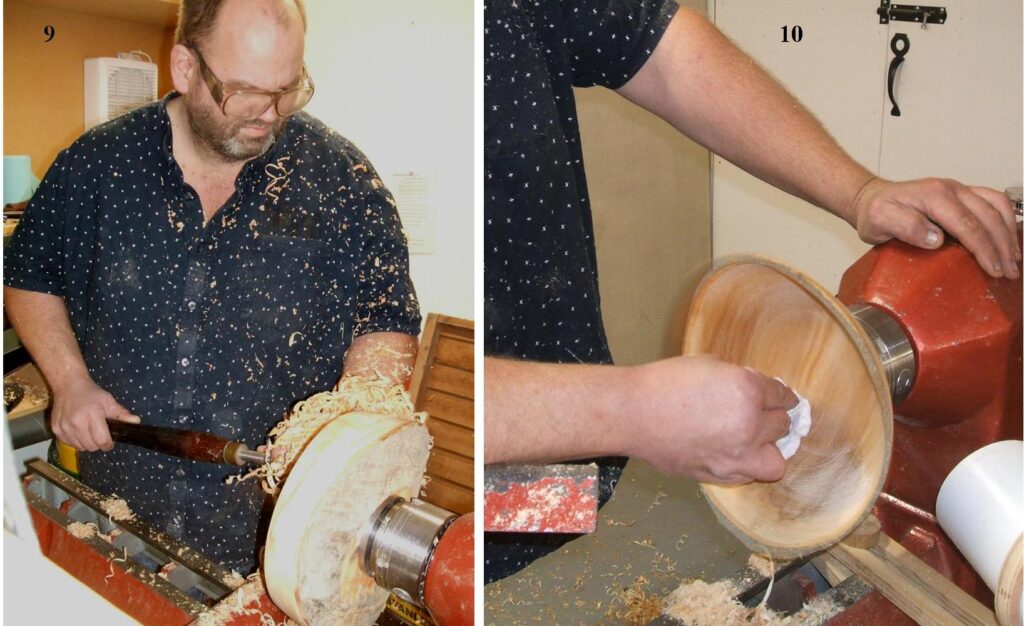

I took a few pictures of the turners at work, here are a few of them.

1, Here we have Alan Smith preparing to get started on his green wood bowl, Alan was using a piece of Sycamore and was going to part turn then complete it at home after it had dried sufficiently to complete the turning. 2, Alan is working on the outside of his bowl, some work has been done on the inside where he has left the wall thickness quite thick to allow him to finish it at a later date.

3, with the wall thickness left quite thick Alan is now taking the inside down to a common thickness before leaving it to dry further. 4, Alan with his green wood bowl ready for the final drying process.

5, here we have Susan Drew making a start on her green wood bowl, Susan was using a piece of green Cherry wood and was going to use the thin wall system for her turning. 6, the external shape progressing well.

7, the external shape almost complete, the shape she chose was beneficial to this type of turning. 8, Susan with her almost finished bowl, there was still some work to do in the finishing but she had cut the bowl to about 3mm in thickness.

9, here we have Richard Comfort working on the outside of his Natural Edged bowl, Richard was also going to use the thin wall approach, the wood is Beech with the bark intact but it was very unlikely that the bark would stay on after cutting to a thin wall. 10, here Richard is trying to dry the surface with the use of a wad of paper, this will assist in the sanding process, stopping the sanding disc he uses from clogging up.

11, here Richard is using his power sander to sand the inside of his bowl, 12, Richard with his finished bowl, he got the side wall down to 2 mm thick but the bark as predicted did not stay on.

13, here we have Dave Line making a Natural Edged bowl from a piece of Whitebeam, Dave was also going to try to get the wall thickness down to about 6mm. 14, with the outside complete, here Dave has turned the piece around and is mounting it on the chuck ready to start the inside.

15, Dave is now busy cutting the inside down to his desired wall thickness, monitoring with double ended callipers as the cuts progressed. 16, Dave with his finished bowl.

17, here we have Geoff Potter also working on a Natural Edged bowl, his choice of wood was a piece of Ash, probably the best wood choice if you want the bark to stay on. 18, here Geoff is working on the external, the ghosting of the outside is clear to see, this comes about because the wood is not fully round at this stage.

19, here Geoff is working on the inside, he would leave it fairly thick in order to complete at a later date after the wood had dried a bit further. 20. inside you will see a recess in the bottom of the bowl, this was to allow this bowl to be re-mounted after it dried, this was a new element on working this type of bowl that Geoff had not done before, but he understood the principle of doing it.

That completes the turning demonstrations, Alan and all 4 turners were given a well deserved show of appreciation and thanked for their involvement.

Our next meeting is on the 14th December 2023, start time of 6.45pm.

You will note this is not our usual pattern of meetings, we have brought forward the final meeting for 2023 due to it’s proximity to the Christmas celebrations.

It’s also our last Competition for the year, an open Competition where you can make or show anything you have made, more than one entry is allowed and it will be judged by the membership present, the overall winner could come from any of the 3 categories judged by the membership, and will be presented with the MacGregor shield. So please enter, the more the merrier.

The winners of the Shield Competitions for the Competitions throughout the year will also be announced and the shields awarded to the 3 winners from the 3 categories.

Here are all the winning entries from last year 2022.

Running alongside the Competition is the yearly GRAND RAFFLE DRAW, we have 101 prizes to be won, most were sourced by our 2 buyers Peter Lawrence and Alan Geddes and some have come from donations the club members have brought in.

Here are some of the prizes to be drawn at the meeting, there will be no choosing what prize you get from any ticket, the organizers will select and draw at random, you may turn down a prize but you will not be allowed to select another. Good luck to you all, tickets will still be on sale right up to 10 minutes before the draw starts.