Our meeting on Thursday 18th July 2024 was another of our Showtime meetings, this one’s presenter was Nick Simpson. These meetings are for the most part very successful and although the turnout was a little disappointing it turned out to be a very enjoyable meeting.

Continue reading “Report on our meeting 18-07-2024 organized by Nick Simpson.”Our next meeting 18-07-2024 organized by Nick Simpson. It’s one of our Showtime meetings.

Start time 6.45pm.

Our next meeting is on Thursday 18th July 2024, it has been organized by Nick Simpson and it’s another of our Showtime meetings.

Continue reading “Our next meeting 18-07-2024 organized by Nick Simpson. It’s one of our Showtime meetings.”Report on our meeting 03-07-2024 organized by Barry Cumming.

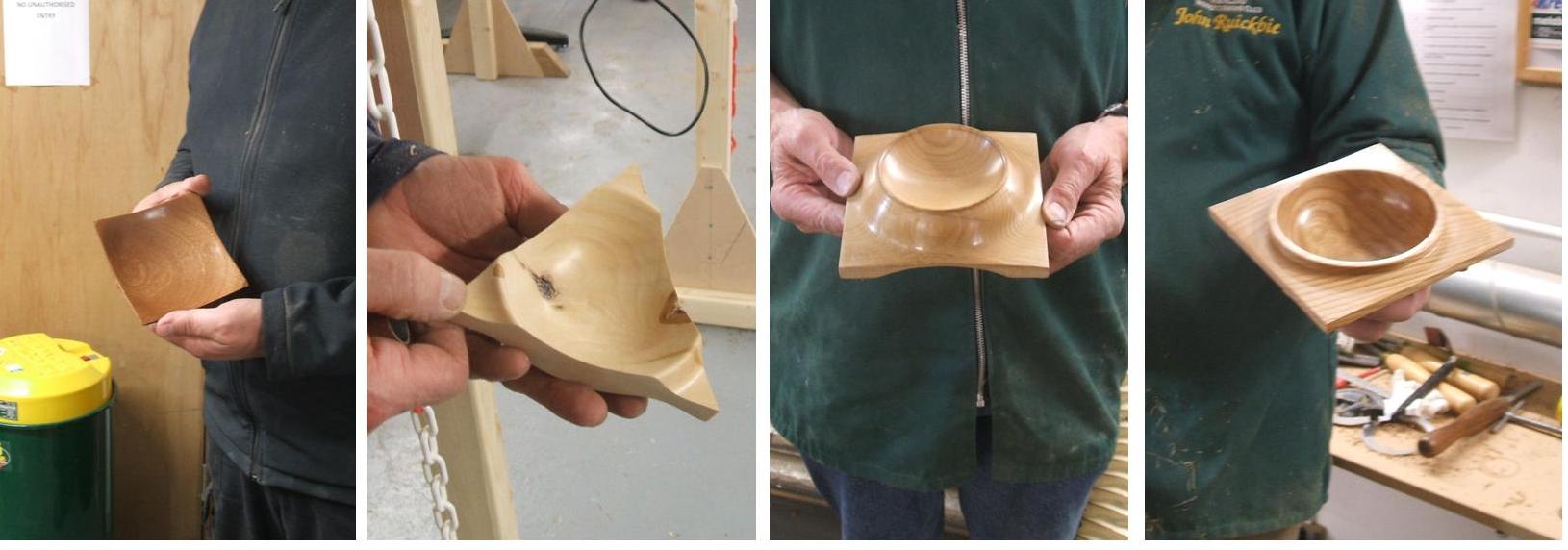

Our meeting on Wednesday 3rd July 2024 was organized by Barry Cumming, Barry wanted to use this meeting to experiment with square or odd shaped bowls as he had not done any of these since he started woodturning. He then organized for 4 more turners to man all our lathes to demonstrate the methods used to make square or odd shaped bowls.

Continue reading “Report on our meeting 03-07-2024 organized by Barry Cumming.”Our meeting this week 03-07-2024 organized by Barry Cumming.

Date and start time, Wednesday 3rd July 2024, 6.45pm, please note the change of date for our meeting, this is due to the Westminster Elections happening on the 4th July.

This meeting has been organized by Barry Cumming and Barry’s theme for the evening is making square bowls, these can be made in a variety of ways some of which you will see at the meeting. Barry has not ventured into making these types of bowls so far with his woodturning and I’m going to partly mentor him for his first square bowl with an audience. He has also arranged for 3 more turners to be involved with making a square bowl, 2 of which I know to be approached from completely different angles.

Continue reading “Our meeting this week 03-07-2024 organized by Barry Cumming.”Report on our meeting 20-06-2024 organized by John Ruickbie.

Our meeting on Thursday 20th June 2024 was organized by John Ruickbie, John had all 5 lathes working on items that were destined to be donated to the club’s open day on the 10th August to be sold as part of our fund raiser programme for the purchase of a Defibrillator for our club house.

Continue reading “Report on our meeting 20-06-2024 organized by John Ruickbie.”Our next club meeting 20-06-2024 organized by John Ruickbie.

Start time 6-45pm.

Our next club meeting is on Thursday 20th June 2024, It’s being organized by John Ruickbie, John has arranged for all 5 lathes to be working, he will be on one lathe with 4 more turners manning the remaining lathes.

Continue reading “Our next club meeting 20-06-2024 organized by John Ruickbie.”Report on our meeting 06-06-2024 organized by Alan Smith.

Our meeting this week was organized by Alan Smith, Alan had the dubious privilege of having to organize the yearly Pub Style Quiz, this he did with an enthusiasm that was difficult to match, he created a set of questions that really set the cat amongst the pigeons, in other words I think Alan was the winner in this quiz.

Continue reading “Report on our meeting 06-06-2024 organized by Alan Smith.”Our next meeting 06-06-2024 organized by Alan Smith.

Start time 6.45pm.

Our next meeting is on Thursday 6th June 2024 it has been organized by Alan Smith and Alan’s subject for this meeting is a Pub Style Quiz. This is the 2nd time we will have done this type of quiz, all the questions will be coming from Alan Smith, most will have a reference to wood and wood turning in some way, but not exclusively so.

Continue reading “Our next meeting 06-06-2024 organized by Alan Smith.”Report on our meeting 23-05-2024 our 2nd Shield Competition organized by Nick Simpson.

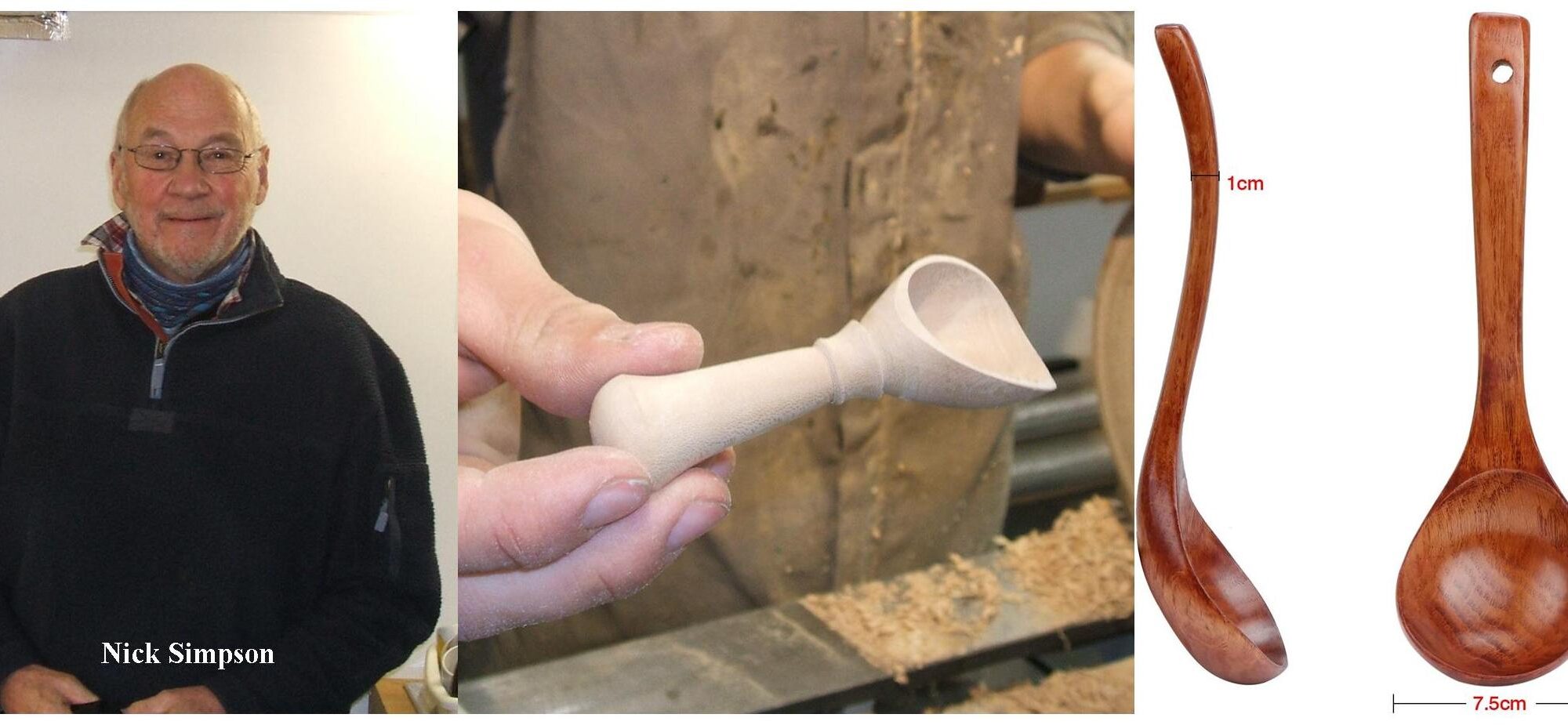

Our meeting on Thursday 23rd May 2024 was our 2nd Shield Competition, it was organized by Nick Simpson and Nick’s theme for the competition was Spoons, Ladles and Scoops. The Novice category had a Scoop to make, the Intermediate category had a Matching Ladle or Spoon to make, the Open category had a matching set of 4 Ladles or Spoons to make.

Continue reading “Report on our meeting 23-05-2024 our 2nd Shield Competition organized by Nick Simpson.”Our next meeting 23-05-2024 our 2nd Shield Competition for 2024 organized by Nick Simpson.

Start time 6.45pm.

Our 2nd Shield Competition for 2024 will be held on Thursday 23rd May 2024, it’s being organized by Nick Simpson, assisted by David Hobson and Susan Drew. Nick’s subjects for this Competition is to make wooden cutlery. He has set a slightly different task for each category, the Novice category are to make a Scoop, the Intermediate category are to make a Matching Ladle or Spoon, the Open category are to make a Set of 4 matching Ladle’s or Spoons.

Continue reading “Our next meeting 23-05-2024 our 2nd Shield Competition for 2024 organized by Nick Simpson.”