Our meeting this week on Thursday the 15th April 2021 was all about Natural Edged Turnings, this meeting was being arranged by Geoff Potter. It had to be changed into a virtual meeting due to the Covid-19 restrictions. However you were all invited to make something along the lines of the criteria requested. The response was very poor, but we were very grateful for the pictures we received from the limited number who took part, those were David Ross, Dave Line, Nick Simpson, Geoff Potter and myself. As Geoff was handling the meeting he chose to make something using a timeline for you all to follow.

I have put Geoff’s timeline presentation in first,

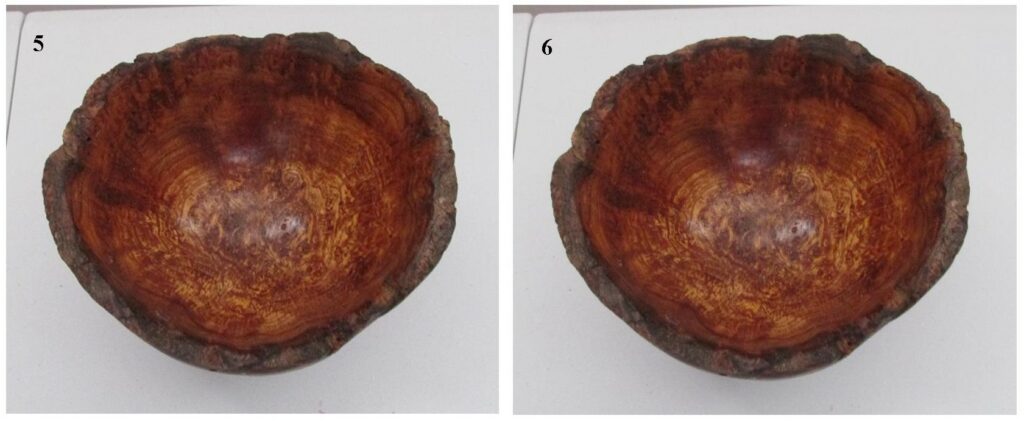

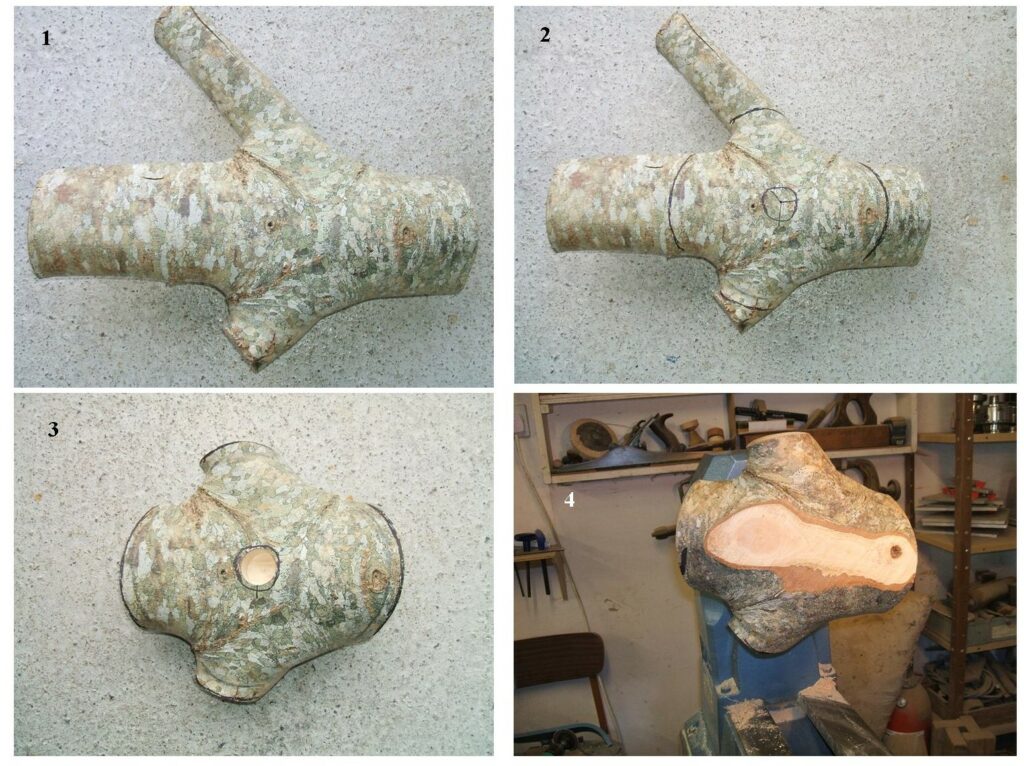

A SIMPLE BIRCH WOOD BURR BOWL

This article is aimed at beginners or the less experienced turners like me.

I was lucky to spot this piece at a friends house– this birch burr was destined to be firewood. It is a large burr surrounding the central stem of a birch tree. The stem is only about 12cm diameter but the burr is c30cm diameter. Picture 1.

I chain sawed the Birch stems off and after chopping a flat area on the burr – I screwed on my faceplate.

This faceplate has to be swapped for my usual scroll chuck on my Record CL3 lathe as it does not fit into my usual scroll chuck. A bit of an extra fiddle!

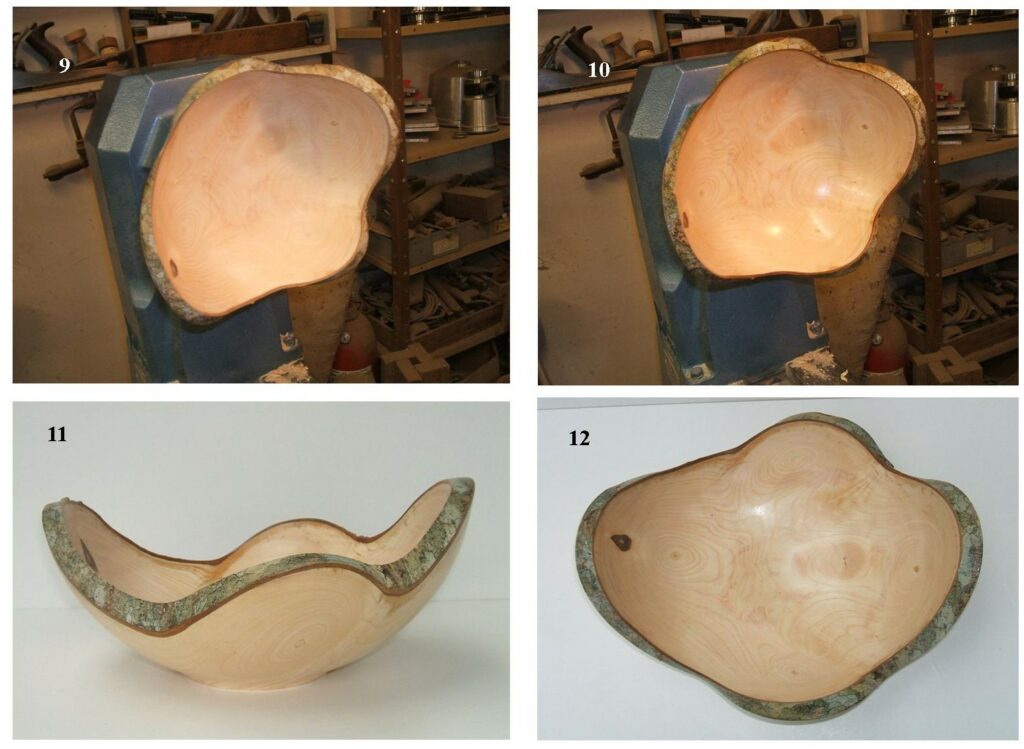

Picture 6, Here’s the outside and base almost done. I left a tenon on the base which fitted my scroll chuck. Test the fit/size with the scroll chuck before you take the bowl off the lathe!

Sand ( power sanding with 120 – 240 – 400 grit ) seal and finish the outside (sanding seal then melamine)

Remove the faceplate.

Pictures 7 & 8, Then reverse the bowl onto the scroll chuck. I cut a groove with the parting chisel at the inside edge to start with. Start hollowing with the bowl gouge.

Sand, seal and finish the inside. I used food safe oil on the inside. I used heavy coats of melamine on the bark edge. Treat all splits and any loose sections with superglue as you go along.

The finished bowl with a natural edge.

I like it chunky.

Not bad for a piece of firewood.

Happy turning! Geoff Potter.

Now for David Ross’s presentation.

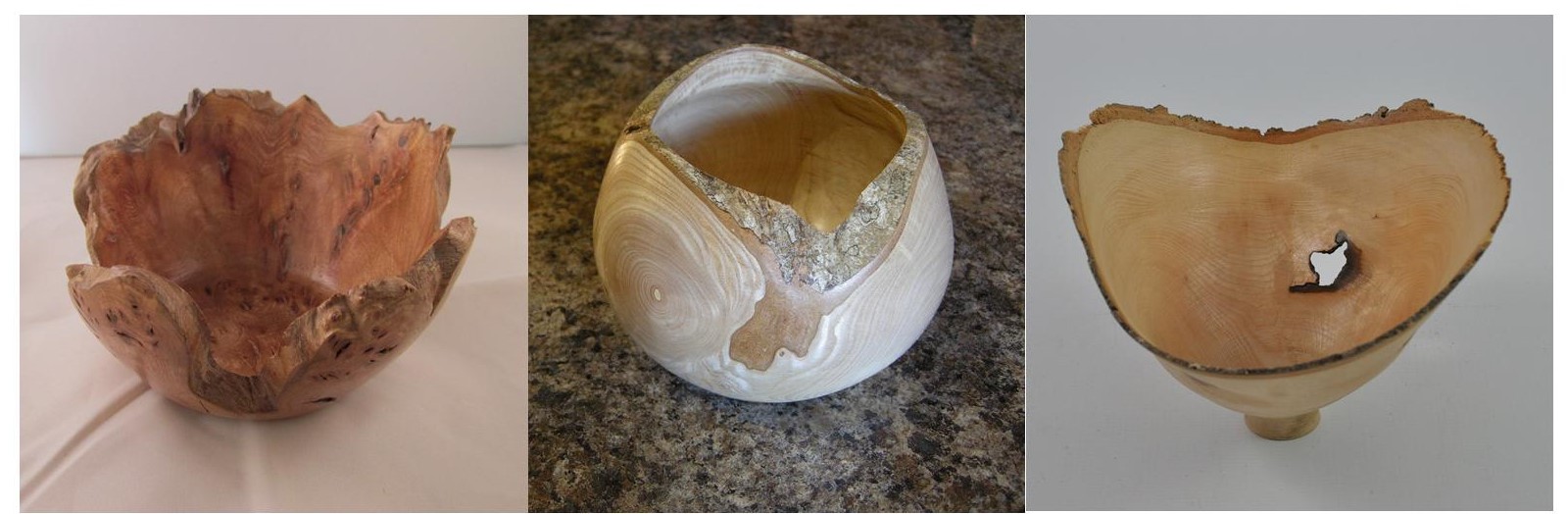

Hello Alec, I have attached several natural edged bowls.

Pictures 1 & 2 is a small burr I turned within the last month Finished in Danish oil, the wood used is Burr Elm.

Pictures 3 & 4 were turned in 2018 to hold a glass candle holder Finished with two coats sanding sealer two coats melamine, the wood used is Ash

Pictures 5 & 6 was turned 2020 two coats food safe oil, the wood used is Alder.

David Ross

Now we have an entry from Dave Line. This is what Dave had to say about his entry.

Hi Alec,

Please find attached a couple of natural edge bowls. The first is made from Ash (I think) and is 150mm dia and 120mm high. The second is made from Copper Beech and is 180mm dia at longest edge and 160 at narrowest edge and is 85mm high.

Stay safe

Dave Line.

Next we have an entry from Nick Simpson. This is what Nick Had to say about his entry.

Morning Alec.

I attach a photo of a natural edge thin vase with a narrow base. It was turned end grain from a branch which blew down in storm Desmond a year or 2 ago. It has warped in almost all directions thanks to 2 branches which have left holes in the sides. It measures 120x100mm.

Best regards

Nick Simpson.

Now for a Natural Edged Bowl I made from a piece of Ash that was kept from an Ash tree that we had to take down due to Ash die back.

Made by Alec Mutch.

Our next meeting will be on the 29th April 2021, this meeting will be our SHOWTIME meeting, Geoff Potter would have been the organiser but due to the Covid-19 situation this meeting will be virtual only. However we do expect that you will let us all see what you have been doing over the past few months, there will be no theme to this meeting you can enter whatever you like and the more the merrier, we are hoping for a good lot of entries.

Do remember the clubhouse remains closed.