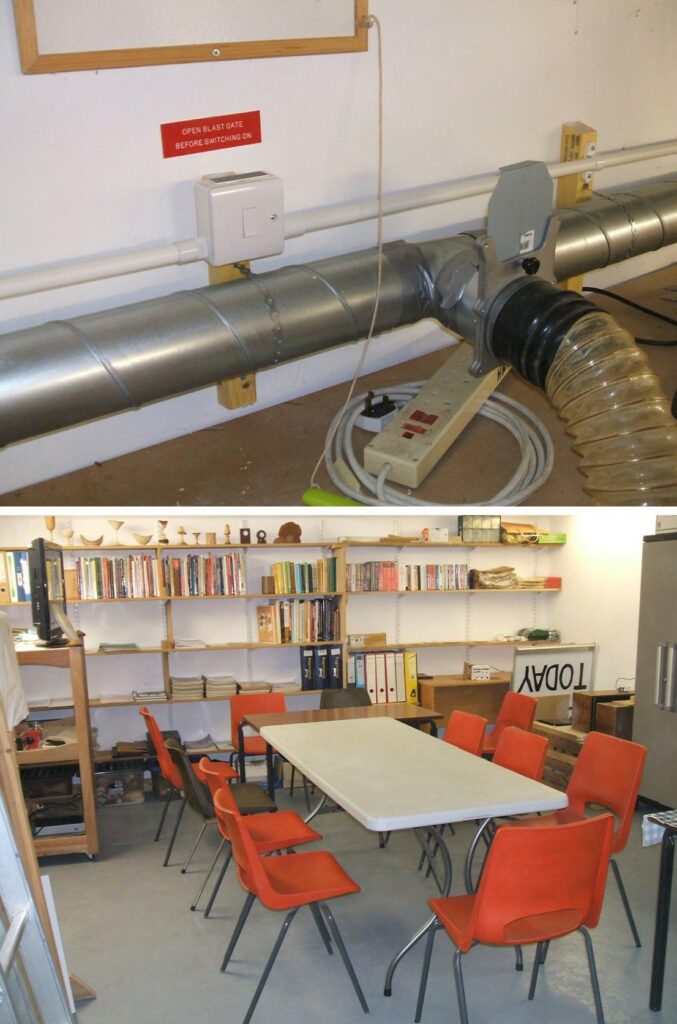

I thought you might like to see what we have done with our club premises as a result of the Covid pandemic. Our club premises needed some upgrading to reduce the possibility of Covid being transmitted to or by our club members. This included having to improve the ventilation, install a full dust extraction system to all 5 lathes, set up a sanitising station, keep very accurate records of attendees for track and trace if it were ever needed, we also managed to increase the space between each lathe by repositioning the machines, this allows us more space for the members who are observing the turners. We also did some general housekeeping by giving all the floors a fresh coat of paint.

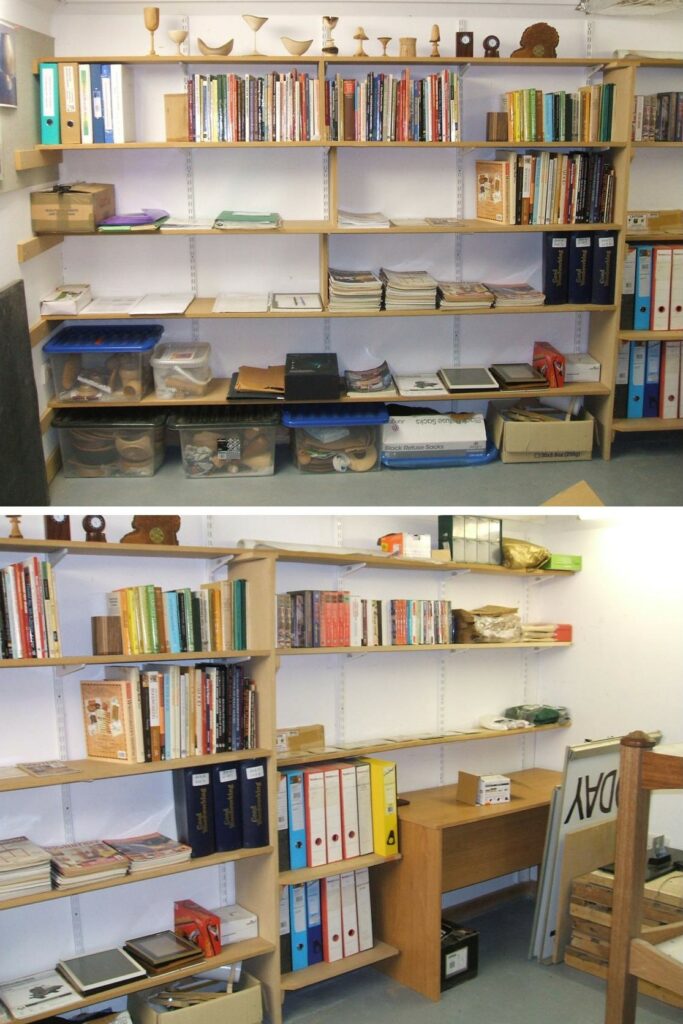

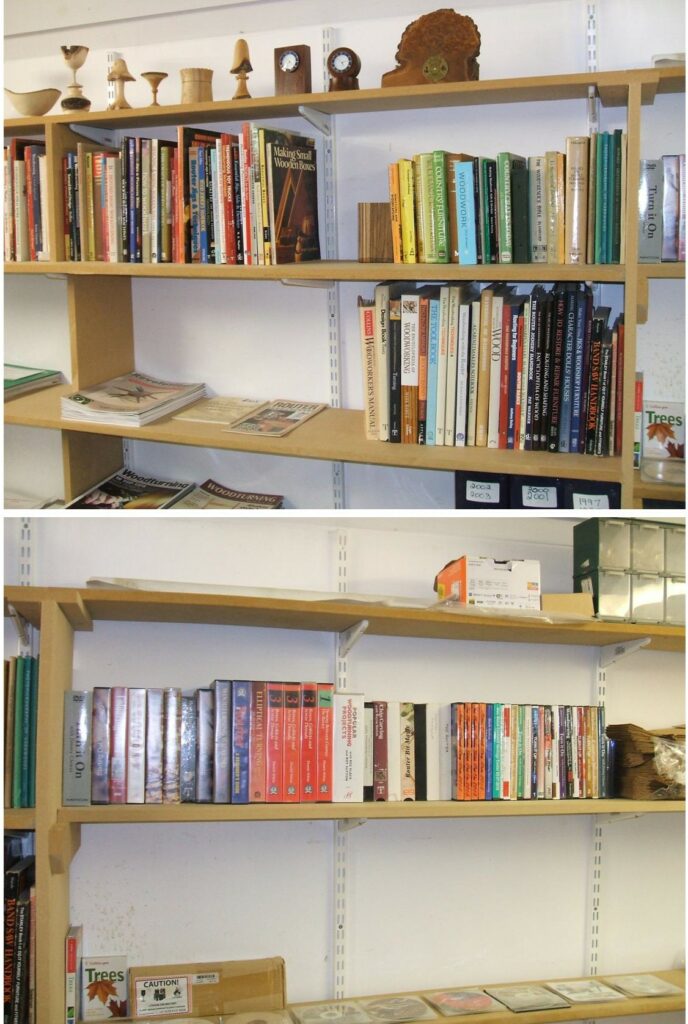

We have removed the office from the main work room and replaced it with a much smaller enclosure that now houses the new dust extractor, it was this change that allowed us to improve the space for each lathe, the library used to be in the office along with some of the club documents, these are now in the kitchen area on a new set of shelves, some changes have also been done to the viewing screens and the camera positions.

Here are a few pictures of the improvements we have done.

The club extends it’s thanks to all of those who took part in the alterations especially John Ruickbie, Bill Munro, Dave Line, Errol Levings, Peter Lawrence, John Cheadle and a little direction from me, Cliff Sim was involved with all the payments. All these members did the work on a voluntary basis with no payments being sought, we paid for the equipment and materials only.

We did have a few member who did not subscribe to the club this year, we hope after seeing what we have done with the premises that those who were members in the past come back again next year 2022, the fee will be the same as this year (£40) but the conditions have greatly improved and we would be very pleased to see you all return.