This was our first meeting after the pandemic restrictions were lifted that turning was involved, and it was good to be back in operation again. We have made some changes within the club to make it much safer for everyone to return, this included installing some ventilation fans and a CO2 monitor, and to combat any dust issues, we are currently installing a full dust extraction system to all the lathes and the bandsaw.

I (Alec Mutch) was tasked with doing the first of a series of single person demonstrations that will take us up to Christmas, this allows us to get the confidence of our members back by limiting what happens in the club and hopefully by that time there may be further reductions in the covid-19 restrictions that will allow us to open up even further. It is our intention to resume our normal practice of having all 5 lathes in operation from January 2022.

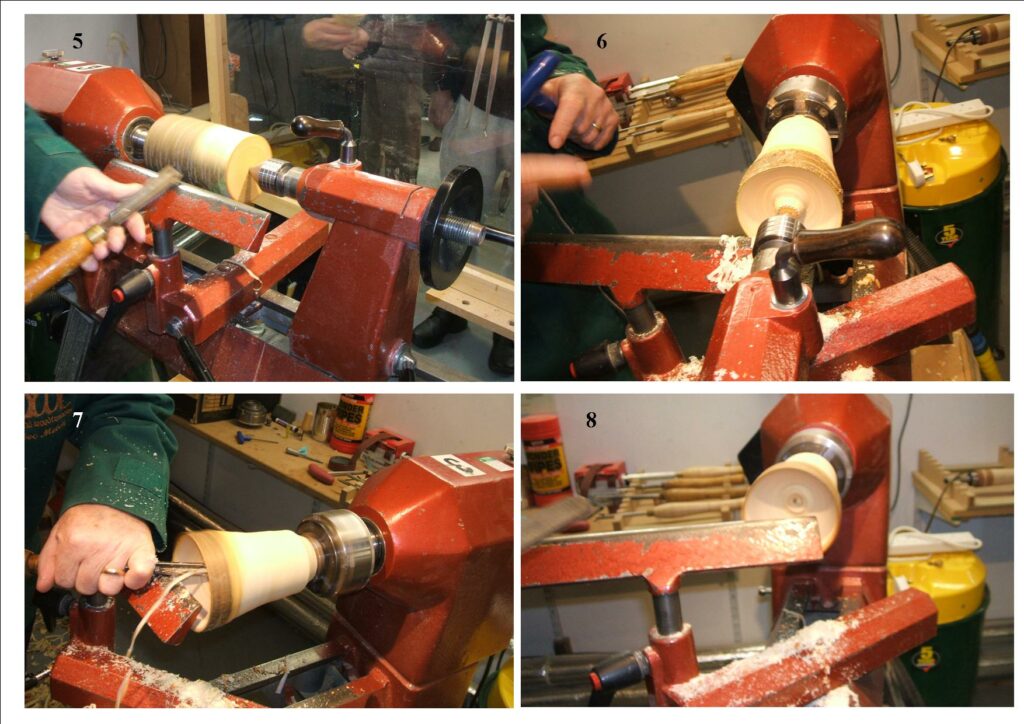

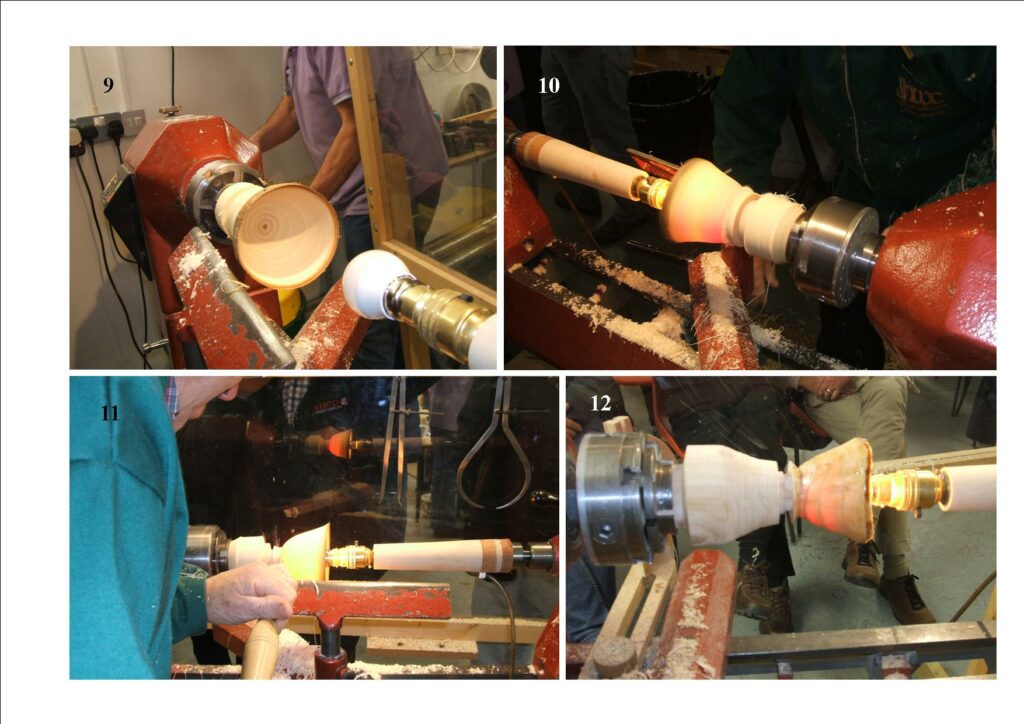

In the meantime here are some pictures of what happened at our meeting on the 2nd September 2021, I’m making a couple of cups/goblets from pieces of branch wood, the first is out of a Cherry branch that is turned wet, the second is from a Leylandii branch that had been dried down to about 20% moisture content.

I hope you have found this first demonstration interesting and informative, I do know that after the demonstration was over several of those present wanted to see how the light stick I used was made, with a view that they too were going to make one.

Our next meeting will be on the 16th September 2021, It’s going to be another single person demonstration by John Ruickbie, John will be making a clock from whisky barrel staves. All will be seated, masks optional when seated, and we may be in a position to have the extraction system working by then.